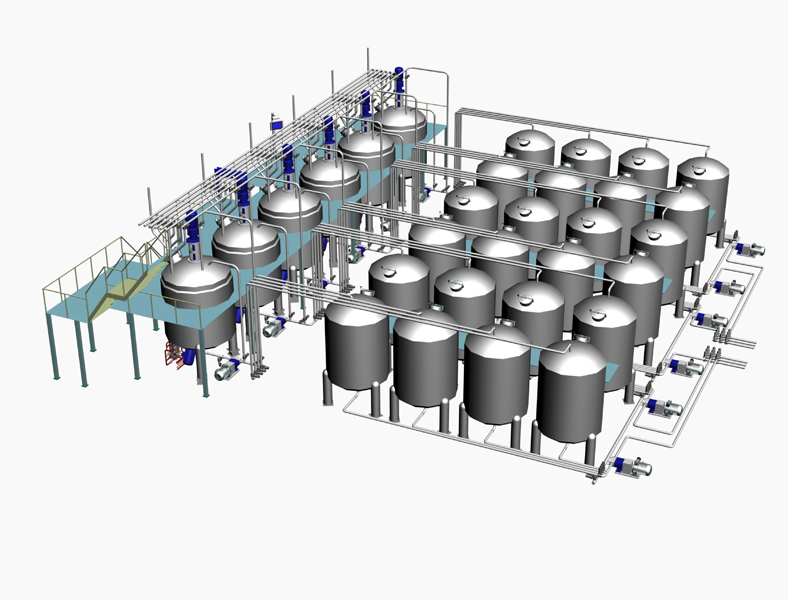

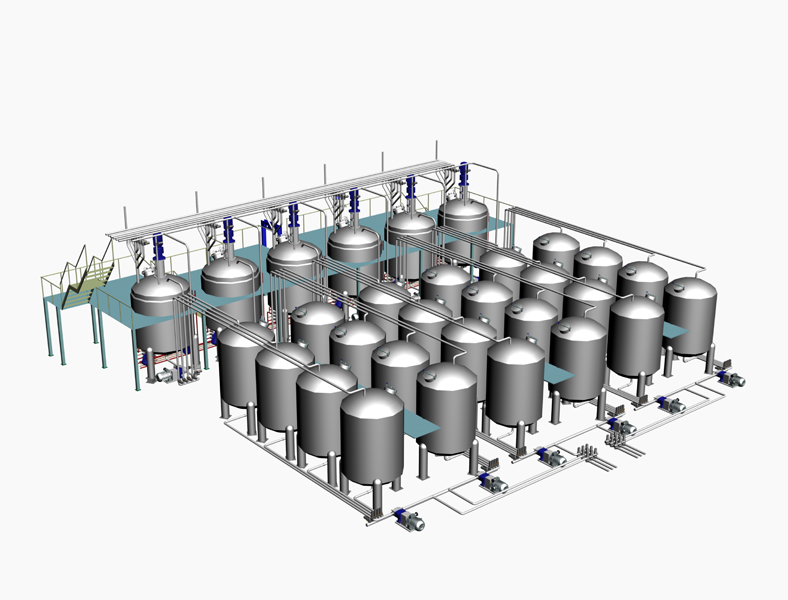

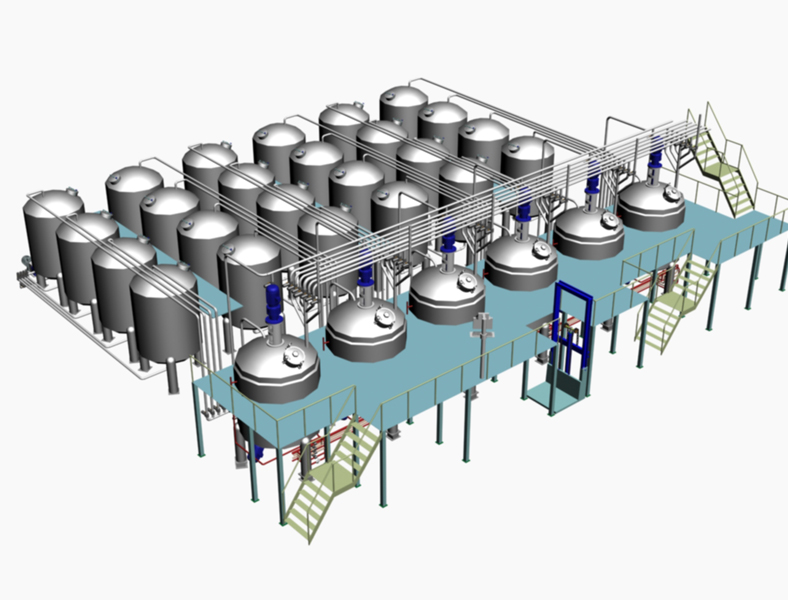

CIP / SIP systems

Planck CIP / SIP system includes tanks and cleaning heads. We offer a variety of customized solutions for different material properties and different production process requirements.

Planck CIP / SIP system includes tanks and cleaning heads. We offer a variety of customized solutions for different material properties and different production process requirements.

Optimal Design, Thorough Cleaning, Energy Saving.

CIP / SIP module Advantages

• 316L stainless steel sanitary storage tanks, CIP variable speed conveyor systems.

• Independent automated design, can be integrated with control system.

• Friendly HMI can be easily set parameters

• Independent insulation system which reduces energy consumption in the production process.

• High-quality modules for perennial trouble-free high efficiency operation.

• Unique technology designed to significantly reduce the foam from the processing.

• The configured backwater system and the external circulatory system can effectively reduce CIP water and energy consumption.

• Upgraded automatic control can automatically detect, add, discharge, display, and adjust the cleaning liquid.

• The system can serve as a public service for the process water, while it can be for on line cleaning, and disinfecting.

Planck Process piping design can be combined with traditional manual operation fluid adapter plate technology and automatic multi-channel valve array technology.

From this, it can realize the pipeline design for concrete connection combining with fully automated operation. By using the multi-channel valve array, CIP / SIP systems applied in a closed loop system can supply water for processing, also for whole production line disinfecting cleaning. The reasonable process piping consists: inlet water pipes, drain pipes, heating up loop cleaning pipes, and self-cleaning pipes. The core components are a variety of pneumatic valves and on-line sensing equipment. In conjunction with the main device, it can achieve:

• temperature automatically rises to the setting.

• Automatically add or adjust the liquid to fit the density required in the tank.

• Hot and cold water self-cleaning for internal and external of the tank.

• The used liquid will be filtered and recycled according to different media.

• Reduce the amount of detergent used.

• Extend the service life of the production equipment.

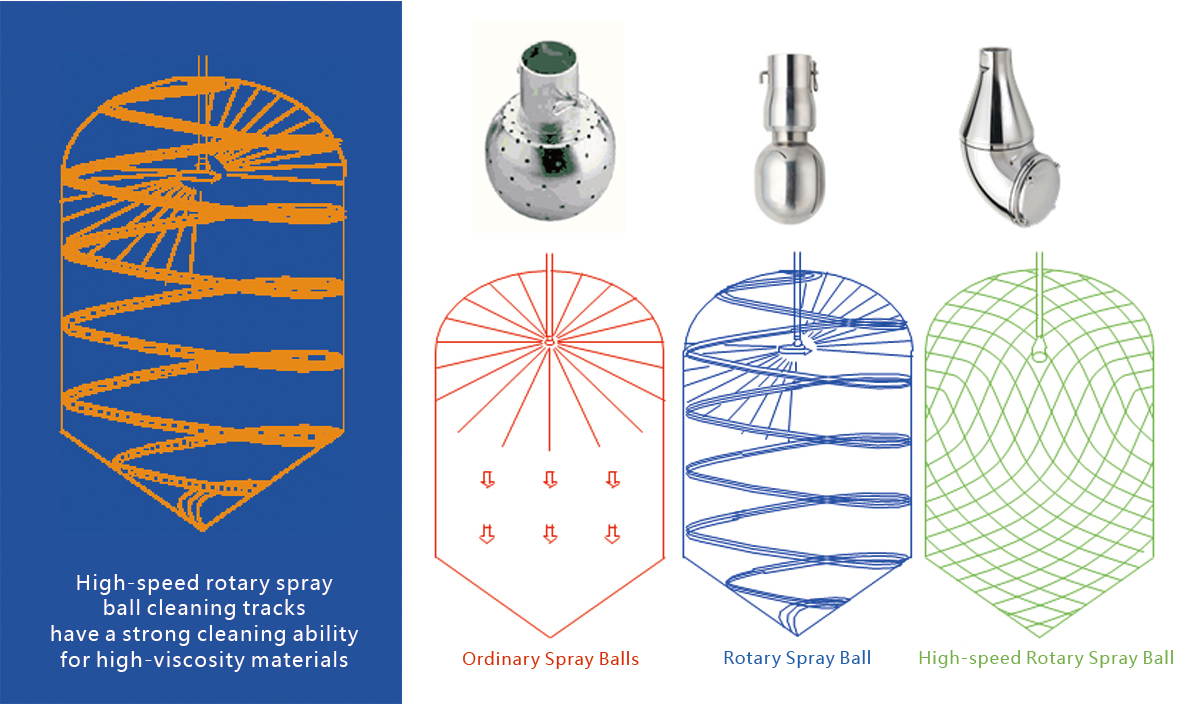

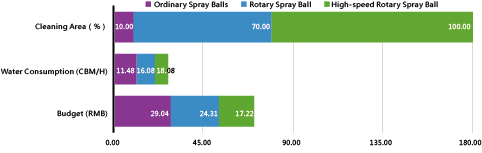

Cleaning head module

Planck CIP / SIP system includes tanks and cleaning heads. We offer a variety of customized solutions for different material properties and different production process requirements.

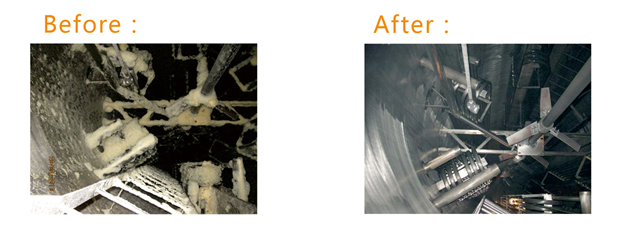

• It can clean the most stubborn viscous material.

• It can have 360-degree no dead ends thoroughly cleaning in the most complex structure tank.

High-speed spray ball:

- Quite obvious advantage in energy saving and cleaning efficiency.

- Clean coverage of up to 99%

- 60% less water consumption than an ordinary spray ball.

• Can serve as a separate service pipeline for hot water for the public service system.

• Can be shared used as online cleaning and online disinfection service.

• Complies with GMP standard for pipeline microorganism control requirements. Effective temperature control can quickly carry out the online cleaning for the pipes and tank.• The system can have continuous cleaning.

• The system can have individual machine cleaning.

ABOUT US

ABOUT US

Modularized Products

Modularized Products

Solution

Solution

Laboratory Innovation

Laboratory Innovation

Service and support

Service and support