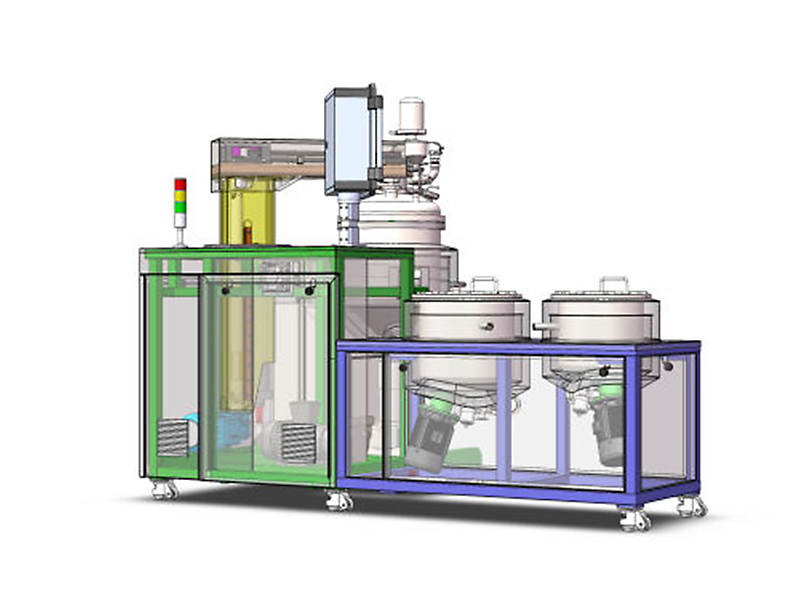

Lift vacuum emulsifying machine

Lifting outer loop vacuum emulsifying machine is Planck’s special for the production of high viscosity and emulsified products with high requirements for the cosmetics and pharmaceutical industries.

Lifting vacuum emulsifying machine

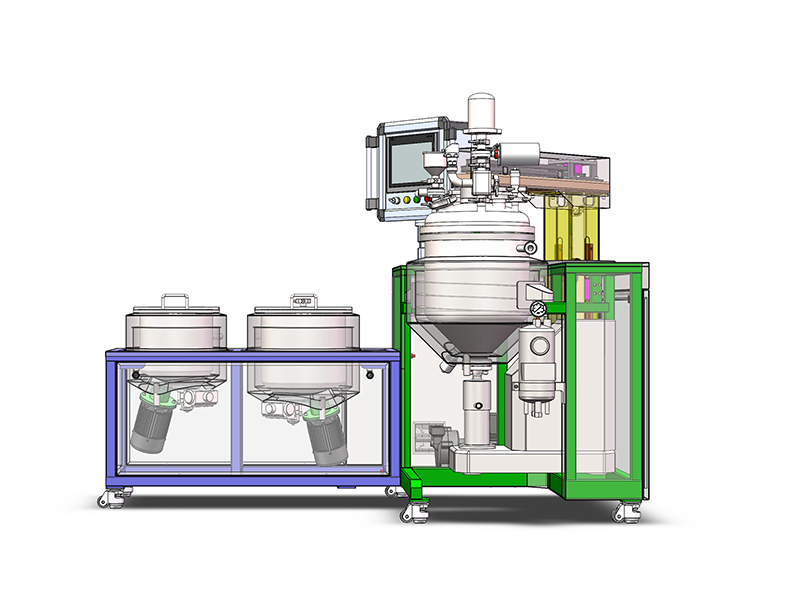

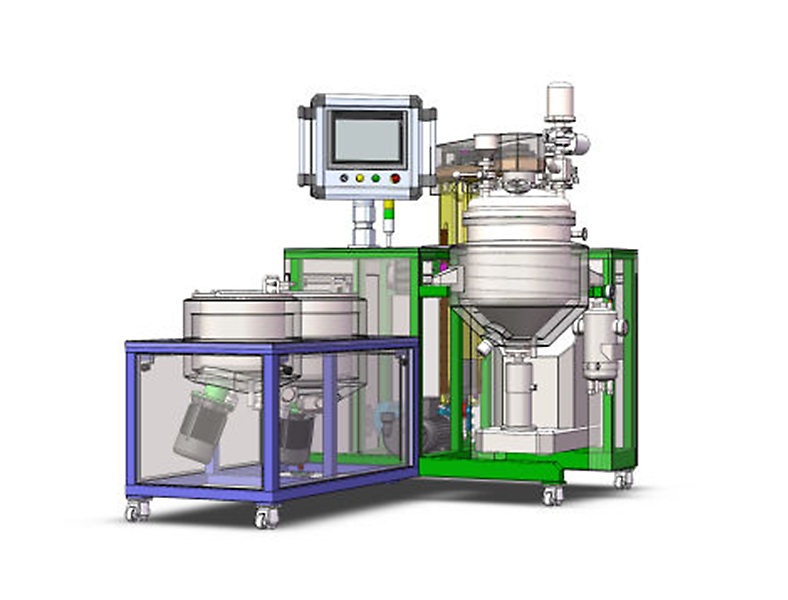

Lifting outer loop vacuum emulsifying machine is Planck’s special for the production of high viscosity and emulsified products with high requirements for the cosmetics and pharmaceutical industries. Its most important features are:

1, the material can be continuously circulated emulsified;

2, the high viscosity material can be mixed thoroughly, no dead ends;

3, the external loop emulsifying machine can be used as a discharging pump; and can be cycling cleaned.

The Stirring part is designed as forward and reverse dual scraping structure, works with the high-speed outer loop emulsifier head.

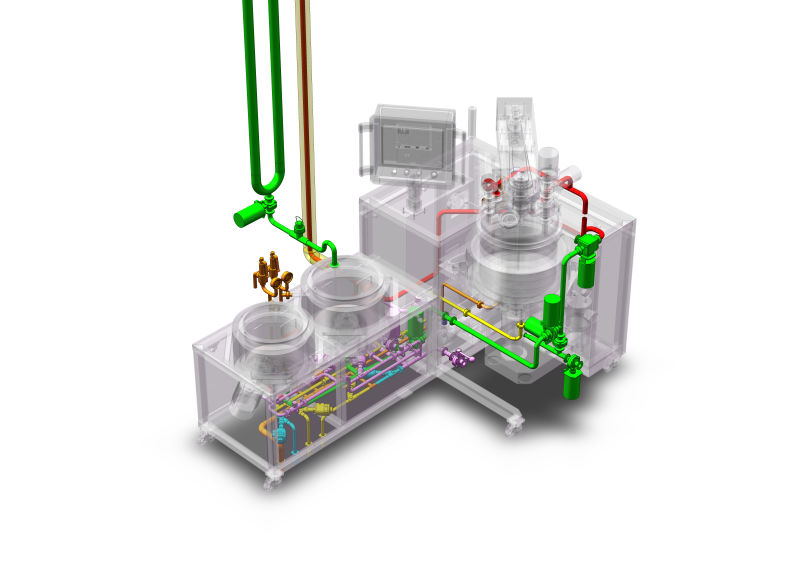

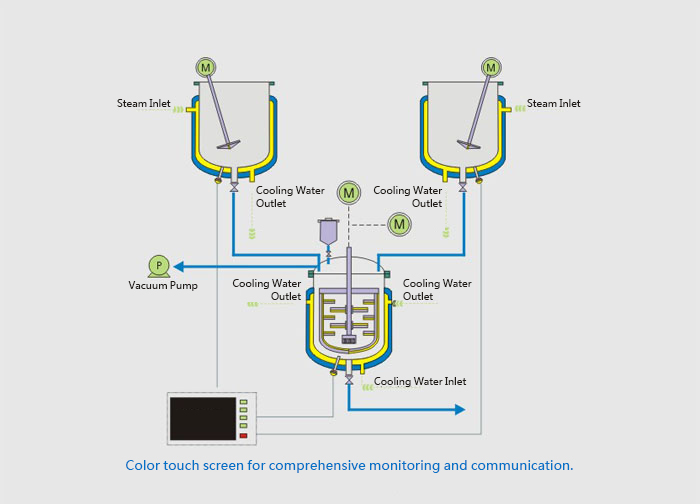

Working Principle

The materials in the water-phase tank and oil-phase tank are heated up and stirred. After they are thoroughly mixed, they will be transferred to the emulsifying tank by vacuum pump. The material will be stirred by the upper part of the central paddle, combined with the PTFE scraper sweeping the wall, the material will be stirred thoroughly and meanwhile be pushed down to the emulsifier at the low part of the central axle. With very high speed emulsifying effect, the material will be seriously cut, sheared, and cracked into 200nm – 2um particles. The bubbles appear during the process will be sucked out promptly in the vacuum status in the tank.

Characteristics

• With hydraulic lifting system, free to lift up and down the lid.

• Mixing system uses inverter for dual scraping stirring, to meet the different requirements of the production process.

• Advanced emulsifier, special structure, reliable seal (mechanical seal from Burgmann Germany), emulsifying speed 0-3500 rpm (LG South Korea inverter)

* Made of imported SUS304 or SUS316L. The tank body and pipes are mirror polished, in full compliance with GMP standards.

* Vacuum anti-foaming can keep the materials in an aseptic hygienic status. The material also can use vacuum suction for transfer to avoid any dust arisen.

• According to the process requirements, the tank can be heated or cooled. The optional heating way is by steam or by electricity.

Standard configuration

◆ Emulsifier, water phase tanks, oil phase tank

◆ vacuum pumps and sync solenoid valves

◆ emulsifier and material filter

◆ hydraulic lifting system and mixing system

◆ stainless steel platform

◆ inverter and electrical control box

Optional configuration

◆ 10.4” color touch screen

◆ Internal PLC

◆ Internal printer

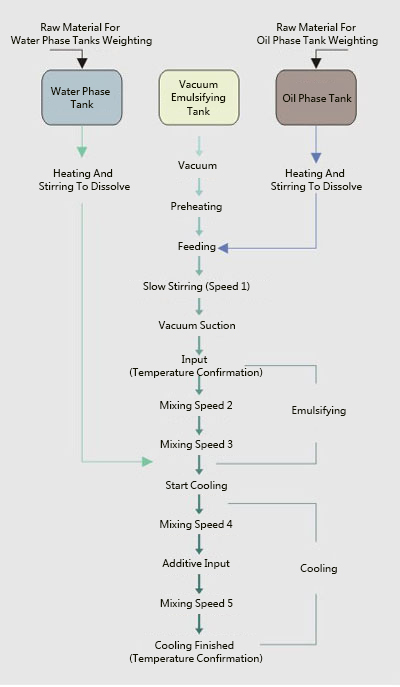

Typical technical process flow

Advanced automatic control system

Vacuum emulsifying machine equipping with advanced PLC control for automatic operations, also equipped with a color touch screen for comprehensively monitoring of the entire production process.

Full automatic control system

| 型号 | 工作容量 | 搅拌功率 | 乳化功率 | 乳化转速 | 真空度 | 加热方式 | 外型尽寸 |

| Model | Working capacity(L) | Blending power(KW) | Emulsifying power(KW) | Emulsifying rotation speed(r/min) | Vacuum degree(-MPa) | Heating method(选择)optional | Outline dimensions W×H×L |

| HFZL-SW50 | 50 | 1.5 | 2.2 | 0-3500 | -0.09 | 电加热和蒸汽加热 Electric heating or steam heating | 250×200×260 |

| HFZL-SW100 | 100 | 1.5 | 4 | 0-3500 | -0.09 | 270×220×280 | |

| HFZL-SW200 | 200 | 1.5 | 4 | 0-3500 | -0.09 | 300×250×320 | |

| HFZL-SW300 | 300 | 2.2 | 5.5 | 0-3500 | -0.09 | 320×250×330 | |

| HFZL-SW500 | 500 | 3 | 7.5 | 0-3500 | -0.09 | 360×250×350 | |

| HFZL-SW1000 | 1000 | 5.5 | 11 | 0-3500 | -0.09 | 400×300×400 | |

| HFZL-SW1500 | 1500 | 5.5 | 15 | 0-3500 | -0.09 | 410×350×400 | |

| HFZL-SW2000 | 2000 | 7.5 | 18.5 | 0-3500 | -0.09 | 430×360×480 |

ABOUT US

ABOUT US

Modularized Products

Modularized Products

Solution

Solution

Laboratory Innovation

Laboratory Innovation

Service and support

Service and support